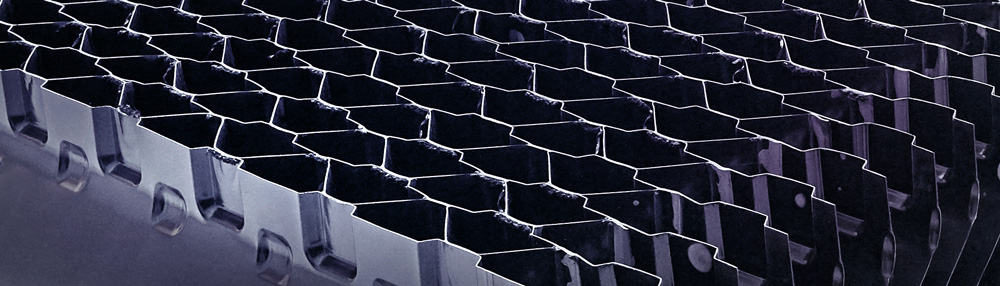

Cellular or honeycomb profile drift eliminator with low pressure drop are manufactured exclusively formed S shaped tubular structure. Individual S shaped corrugated sheets are bonded with subsequent layers to form the honeycomb like structure with single bank double pairs. Droplet separator ribbing elements with honeycomb cellular structure made of thermoformed assembled rigid sheets for vertical air flows. Due to due to thermally welded foils with clamps for connections and greater naps, they have higher strength.

This type of drift eliminator is a nesting cellular PP/ PVC UV protected type design with minimum resistance to air flow of fans. Low drift rate is paramount in terms of an eliminator design and cellular type has the lowest drift loss about 0.001 %. The drift modules are resistant to rot, fungi, bacteria and inorganic/organic acids. Thermal resistance up to 80 °C, fire retardant and negligible or zero maintenance are some other advantages of this type of drift eliminators.