Generally, air flow through the tower is applied in two major methods; •Natural Draft •Mechanical Draft

In natural draft type of cooling towers, heat transfer is completely occurred by natural convection via air circulating inside the cooling tower and warm, moist air naturally goes up due to the density difference with respect to the outside air, which produces an air flow through the cooling tower. This type of cooling tower isn’t in our product portfolio.

In mechanical draft type, air fans are used to circulate air through the cooling tower and generally are applied in two methods, induced draft and forced draft which are explained in different types of cooling towers section.

The use of Mechanical Draft Cooling Towers allows flexible design to satisfy process requirements and environmental conditions. The Mechanical Draft Cooling Tower design furthermore guarantees great flexibility. For example, individual cells can be serviced and, if necessary, drained while the system is in operation.

In mechanical draft type, fan machinery system is very important segment for thermal performance and power consumption. Therefore this segment is very sensitive and all care consideration for selection and designation of fan machinery equipment shall be paid.

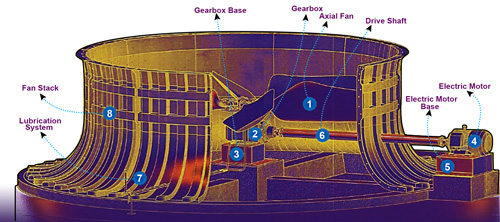

Depends on type of cooling tower and designation criteria, fan machinery system can contain: •Axial Fan •Gear Reducer •Electric Motor •Gera Motor •Belt & Pulley •Drive Shaft •Frequency Convertor •Gearbox Base •Electric Motor Base •Lubrication System